Inspecting Wire Rope Slings

January 21, 2026 2026-01-21 9:44Inspecting Wire Rope Slings

Inspecting Wire Rope Slings

Inspecting Wire Rope Slings

Wire rope slings are essential for lifting, hoisting, and moving heavy materials across many industries. But like any tool, they can wear out or become damaged over time. That’s why it’s important to inspect wire rope slings before each use to make sure they are safe and in good working condition.

Here are 10 key things to check during your pre-use inspection:

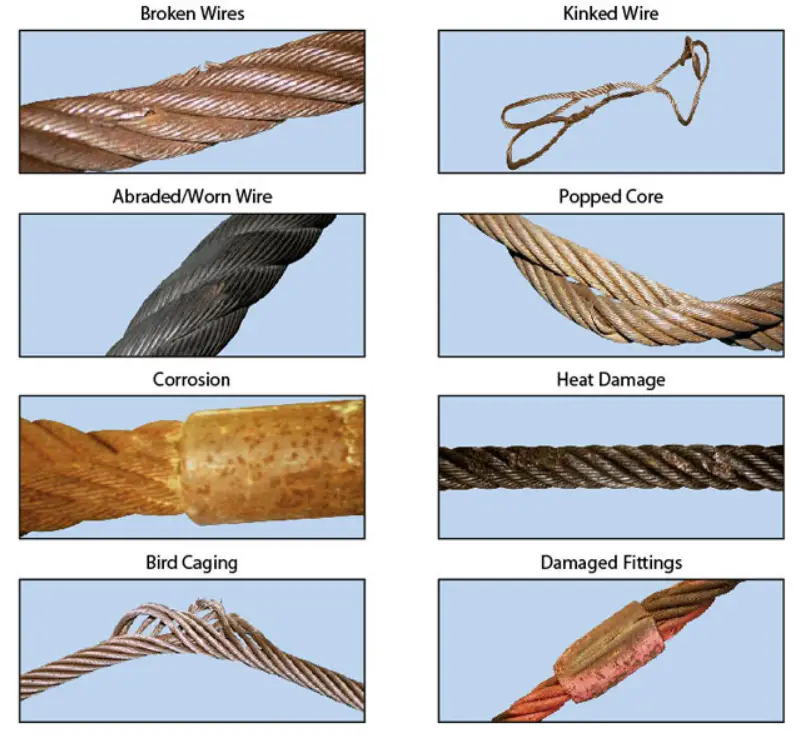

- Look for Visible Damage

Before using a sling, scan it closely for any signs of cuts, kinks, crushed sections, knots, bird-caging (where the wires spread out), or any other deformation that could weaken the rope. - Check for Rust or Corrosion

Rusty or corroded wire can become brittle and is more likely to fail under load. - Inspect the Fittings and End Terminations

Make sure the end connections are tight, secure, and free from damage. Any loose or bent fittings are a red flag. - Look for Broken Wires

Examine the wire strands carefully. Broken wires can be hard to see, so try running a cloth along the rope — if the cloth snags, there may be broken strands. A few broken wires might be allowed, depending on manufacturer guidelines — but when in doubt, have a qualified person inspect it. - Check for Stretching or Deformation

Any unusual stretch, elongation, or change in diameter could mean the sling has been overloaded or damaged. - Look for Exposed Core

If the internal core of the rope is visible, the sling has lost significant strength and should be taken out of service. - Heat or Burn Damage

Watch for signs of heat exposure such as melted areas, discoloration, or charring. These indicate the sling may have been compromised. - Verify the Sling Tag

Make sure the manufacturer’s tag is attached, and that you can clearly read the serial number and rated load capacities. - Follow Manufacturer’s Inspection Guidelines

Always refer to the sling manufacturer’s inspection procedures — they may include extra steps beyond the basics. - Tag Out Damaged Slings Immediately

If you find any issues that could make the sling unsafe, remove it from service right away and tag or lock it out so no one else accidentally uses it.

Sling Damage Examples

Important Safety Reminder:

If you spot any of these types of damage on a sling — no matter how minor it may seem — take it out of service immediately. Don’t wait for more obvious damage to appear.

Once a sling is removed from service, it must be destroyed or permanently disabled so it can’t be used again.

Never ignore damage and never try to fix a damaged sling in the field with temporary repairs — this is extremely dangerous.

Regular proper inspections are the best way to prevent accidents. And if you’re ever unsure about a-sling’s condition, err on the side of caution and do not use it.

To Wrap Up:

Inspecting your wire rope sling before use is a simple step that can prevent serious accidents. Take a few minutes at the start of each shift to look for damage, wear, or anything unusual. When in doubt — tag it out and report it.