Understanding Respiratory Protection Through Online Safety Training

Understanding Respiratory Protection Through Online Safety Training

In industries and workplaces where workers face respiratory hazards—such as exposure to harmful dust, fumes, vapors, or gases—adequate protection is vital. Respiratory protection ensures that employees remain safe by filtering or isolating hazardous contaminants from the air they breathe. Occupational Safety and Health Administration (OSHA) Standard 1910.134 outlines the requirements for proper respiratory protection programs in workplaces to maintain safety and compliance.

This standard serves as the backbone for a comprehensive respiratory protection program. However, to ensure all employees understand the protocols and maintain compliance, online safety training and safety courses play an important role. Online safety and health training allow employers and employees to access education remotely, making it easier to meet OSHA standards, stay informed on updates, and prepare for emergency situations.

Understanding the requirements, types of respirators, proper use, fit testing, and other procedures related to respiratory protection can significantly reduce workplace risks. This blog will cover all these critical areas in detail.

What Is a Respirator?

A respirator is a protective device worn by workers to reduce or eliminate exposure to harmful airborne contaminants. These devices work by either filtering out harmful particles or providing a clean source of air for workers to breathe. Respirators can include different types, such as filtering respirators and supplied-air systems, depending on the specific hazard involved.

The use of respirators is vital for employees working in hazardous conditions, such as exposure to chemicals, harmful particulates, or toxic gases. Proper implementation of a respirator program ensures that workers are protected from these hazards, thereby improving workplace health and safety.

Why Is a Respirator Program Necessary?

A respirator program is necessary because hazardous airborne contaminants can cause serious health risks, such as lung disease, asbestosis, silicosis, chemical burns, and other respiratory conditions. A properly implemented respirator program helps ensure that employers and workers take the appropriate steps to prevent exposure.

The key objectives of a respirator program include:

- Protecting Worker Health: Ensuring workers are not exposed to harmful particles, vapors, or gases.

- Ensuring Compliance: Adhering to OSHA standards and other regulatory requirements to avoid fines and legal complications.

- Promoting Awareness: Teaching employees about the hazards of specific airborne contaminants and proper respirator use.

- Preventing Accidents: Providing workers with training and clear instructions to ensure respirators are used correctly in emergencies or hazardous conditions.

Employers can meet these objectives through effective online safety training, safety courses, and regular employee education. Online safety and health training offer flexibility and accessibility, ensuring that workers and employers stay informed about proper practices and new developments in occupational safety and health.

Types of Respirators

There are several types of respirators used depending on the level of protection needed, the type of hazard, and the circumstances. Understanding these types is key for compliance and employee safety.

- Air-Purifying Respirator (APR)

- These respirators use filters to remove contaminants from the air.

- Example: Disposable N95 respirators used in medical settings or industries with airborne particulate exposure.

- How it Works: APRs filter out particles, gases, and vapors by pulling air through a filter or cartridge.

- Powered Air-Purifying Respirator (PAPR)

- PAPRs use a motor to draw air through a filter and deliver it to the worker’s breathing zone.

- They are less physically demanding than traditional APRs, especially for workers in physically taxing roles.

- Example: Workers exposed to toxic dust during hazardous construction or chemical manufacturing.

- Supplied-Air Respirator (SAR) or Airline Respirator

- These respirators supply clean, breathable air from a separate source, such as an air compressor.

- Often used in environments with extremely high concentrations of contaminants.

- Example: Confined space workers or firefighters.

- Self-Contained Breathing Apparatus (SCBA)

-

- SCBAs provide workers with a self-contained, independent source of air.

- Example: Firefighters, hazardous material responders, and emergency workers.

- SCBAs are vital in situations where external air cannot be purified or used as a supply source.

Employers must ensure that the choice of respirator is appropriate for the specific hazard employees face. Comprehensive online safety training can help workers identify their respirator types and their intended applications to ensure proper use and familiarity with protective measures.

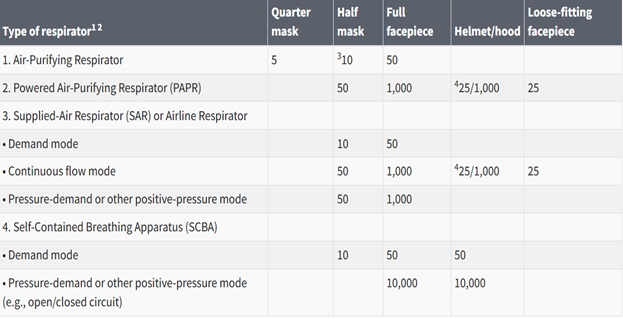

Table1: Types of Respirators

Table1: Types of Respirators

1910.134 Respirator Protection

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.134

Where Respirator Use Is Not Required

Not all workplaces require respirators. According to OSHA standards, respirators may not be necessary if:

- Exposure levels to contaminants are below permissible exposure limits (PELs).

- Workers are using engineering controls like proper ventilation to reduce exposure.

- Proper administrative controls (job rotations, safe work practices) reduce the need for respirators.

Employers should always assess their work environments and conduct risk assessments to determine the necessity of respiratory protection. Online safety training can be used to educate employees about the importance of workplace assessments and hazard analysis.

Fit Testing

Fit testing is critical to ensure that respirators fit correctly and provide adequate protection. Poorly fitting respirators can leave workers exposed to harmful contaminants. There are two primary types of fit testing:

- Qualitative Fit Test (QLFT)

- This test determines the fit of a respirator by testing the wearer’s ability to detect a test agent (such as a bitter or sweet solution).

- If the worker can taste the solution, the respirator does not fit properly.2. Quantitative Fit Test (QNFT)

3. This test uses a machine to measure the amount of leakage into the respirator to determine its effectiveness.

4. QNFT provides a numerical assessment of the respirator’s fit, ensuring a precise analysis of protection levels.

Employers are responsible for conducting fit tests and ensuring their employees’ respirators fit properly before they are used in the workplace. Regular testing schedules are essential, especially if changes in facial structure or weight could alter the fit.

Medical Evaluations

Before workers are assigned respirators, they must undergo a medical evaluation to ensure they are fit to wear respiratory protection. These evaluations assess the worker’s ability to perform physical activities while using a respirator and ensure that underlying health conditions won’t hinder its proper use.

Employers should incorporate medical evaluations as part of the pre-assignment process or any time conditions change (e.g., weight gain, lung disease diagnosis, or other health changes).

Maintenance and Cleaning

Proper maintenance ensures that respirators remain effective and safe for use. Employers must establish schedules and procedures for:

- Cleaning and Disinfecting: Removing contaminants and debris from respirators.

- Storing: Keeping respirators in a clean, dry location to prevent contamination.

- Inspecting: Checking respirators regularly for damage or defects.

- Repairing: Fixing damaged respirators or replacing faulty components as necessary.

- Discarding: Disposing of respirators that can no longer provide proper protection.

A well-structured maintenance program helps ensure that respirators are always ready for use. Employees must also receive training in these maintenance procedures, and online safety and health training is an excellent way to make these schedules and actions clear and consistent.

Online Safety Training and Education

Safety training is the cornerstone of a successful respiratory protection program. Workers must be trained on:

- Understanding respiratory hazards: The types of contaminants and their effects.

- Proper respirator use: How to put on, remove, and maintain respirators.

- Recognizing when respirators may not be-sufficient: Such as changing environmental conditions.

Employers must ensure employees are confident and well-informed through continuous education, and safety and health training are an efficient way to meet this training requirement.

Positive vs. Negative Pressure Respirators

Finally, it’s essential to distinguish between two common types of respirators:

- Positive Pressure Respirators: Maintain higher pressure in the breathing zone to prevent contaminants from entering.

- Negative Pressure Respirators: Rely on the worker’s inhalation to pull air through the filter, creating a slight vacuum.

Both systems provide necessary protection but operate differently and are selected depending on workplace hazards.

Summary

OSHA’s Respiratory Protection 1910.134 standard is essential for ensuring worker health in environments with airborne hazards. A respirator program promotes safety by addressing the selection, use, maintenance, and training of respirator use. Whether using air-purifying respirators, supplied-air respirators, or SCBAs, employers must provide comprehensive safety training and implement fit testing, medical evaluations, and maintenance procedures. Online safety training and safety courses can streamline this education by ensuring workers are prepared, compliant, and confident in using their respirators effectively. Whether in construction, healthcare, or hazardous response scenarios, proper education and safety training can save lives.

Author: Dr. O’Neil G. Blake, Chief Executive Officer (CEO) of OSHAccredited Safety Institute

MS., MBA., MSc., BSc, CSP., ASP., CSHM., CSMP., MRSA.

Date: 12-14-2024