Excavation and Trenching Safety: Protecting Workers in Construction

Excavation and Trenching Safety: Protecting Workers in Construction

Excavation and trenching are among the most hazardous construction operations. From installing pipelines to constructing building foundations, these activities are crucial yet perilous. Understanding the Occupational Safety and Health Administration’s (OSHA) Excavation standards, specified in 29 CFR Part 1926, Subpart P, is essential for maintaining safety and compliance in such operations. Safety and health training in this area is critical for employees especially those in the construction sector. Online safety training with carefully crafted safety courses can make a significant difference in creating employee awareness.

Understanding Excavation and Trenching

Excavation refers to any man-made cut, cavity, trench, or depression in the earth’s surface formed by earth removal. Trenching is a type of excavation in which the depth is greater than the width, but not wider than 15 feet. These activities are integral to many construction projects but come with significant risks, including cave-ins, falls, hazardous atmospheres, and falling loads. Professionals who offer online safety training should ensure that their safety courses are tailored to meet OSHA compliance standards as well as best practices of the safety and health industry.

Dangers of Excavation and Trenching

Excavation and trenching pose significant dangers, including the risk of cave-ins, which can bury workers under thousands of pounds of soil. Falls into trenches and accidents involving heavy machinery are also common hazards. Exposure to hazardous atmospheres, such as toxic gases or low oxygen levels, can threaten workers’ health and safety. Additionally, the risk of falling loads from nearby equipment can result in severe injuries or fatalities. Conducting proper safety and health training and installing protective systems is crucial to mitigate these risks.

The Importance of Excavation and Trenching Safety in Construction

Excavation and trenching are important in construction as they form the foundation for various structural elements. These processes enable the installation of essential infrastructure, such as pipelines, sewage systems, and utility lines, ensuring the proper functioning of buildings and urban areas. They also facilitate the creation of building foundations, which are vital for the stability and longevity of any structure. Excavation and trenching allow for the accurate grading and leveling of sites, essential for effective water drainage and landscape management. Moreover, these activities are critical for laying the groundwork for roads, bridges, and other transportation networks. By creating necessary spaces for underground facilities, excavation and trenching contribute to the efficient use of land and space. They also support environmental sustainability by enabling the installation of systems like stormwater management and renewable energy infrastructure. Overall, excavation and trenching are foundational to modern construction, playing a key role in both the development and maintenance of built environments.

The Importance of OSHA Standards

OSHA’s Excavation standards aim to protect workers from the inherent dangers of excavation and trenching activities. These regulations, found in 29 CFR Part 1926, Subpart P, outline specific requirements to safeguard workers’ health and safety. Key elements include:

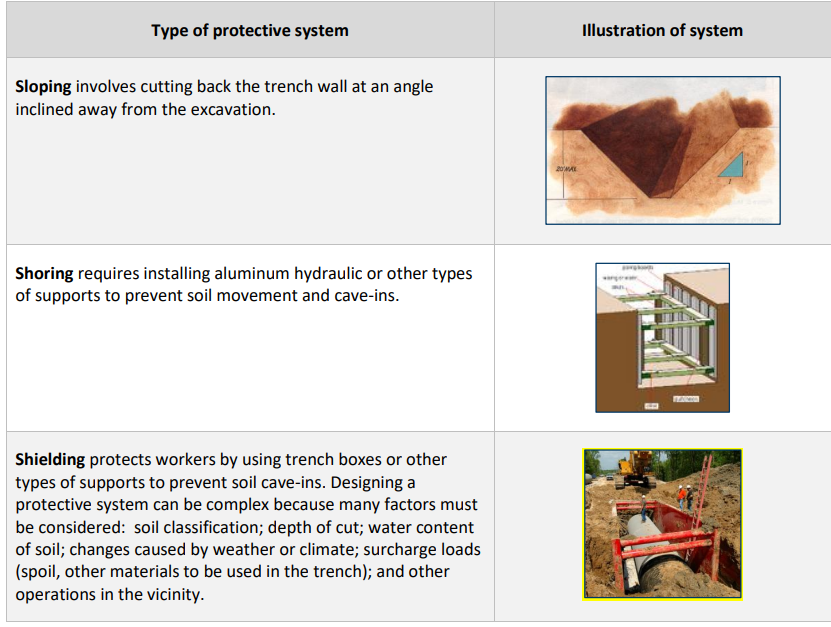

- Protective Systems: These are essential to prevent cave-ins, the most significant hazard in trenching and excavation. Protective systems can include sloping, shoring, and shielding:

- Sloping involves cutting back the trench wall at an angle inclined away from the excavation.

- Shoring supports the trench walls to prevent movement.

- Shielding uses trench boxes or other supports to protect workers within the trench.

Protective Systems

There are different types of protective systems that is taught in health and safety training: Namely shielding, shoring and sloping

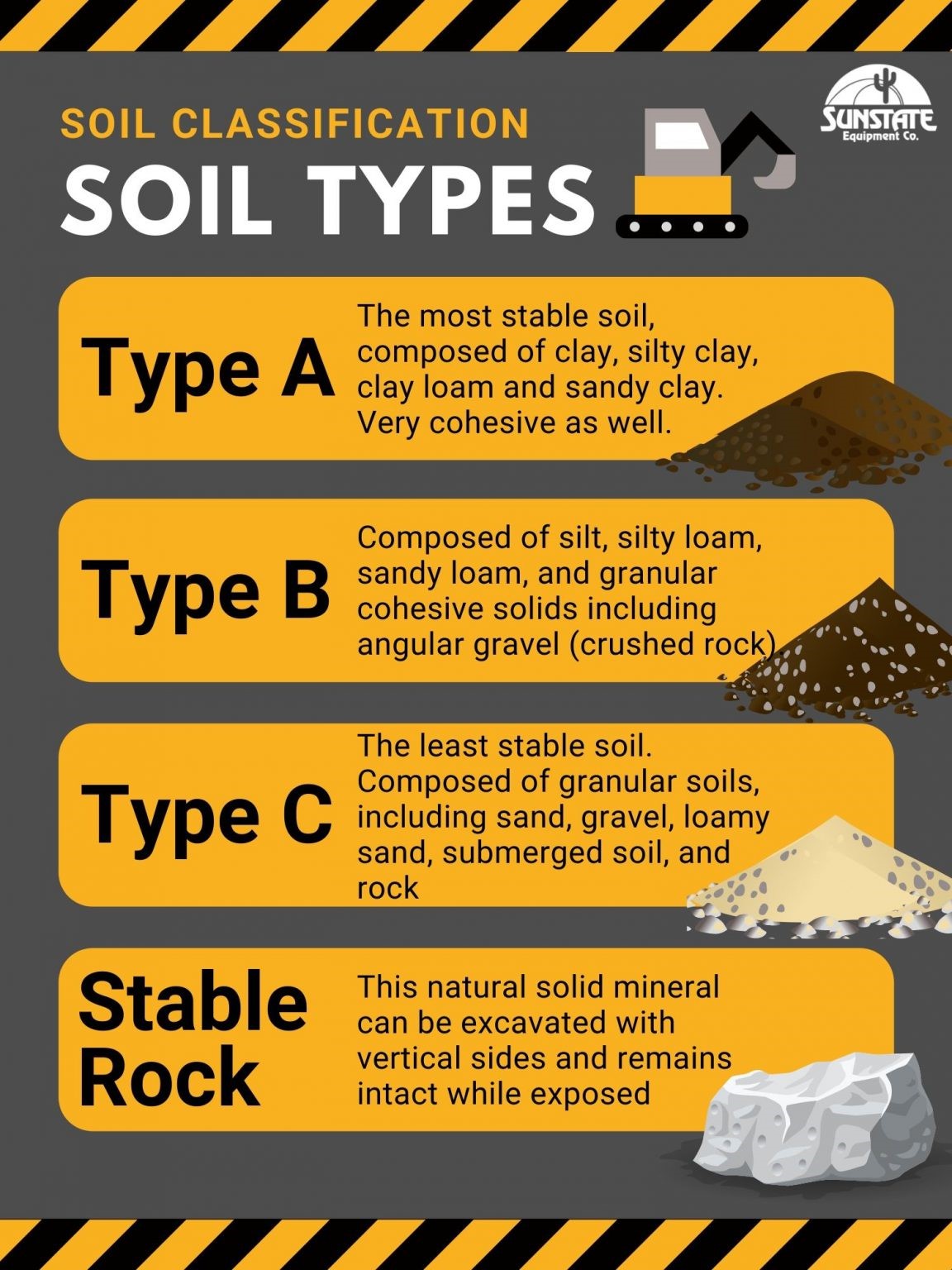

- Soil Classification: Understanding soil types is critical as different soils have varying stability. OSHA classifies soil into four categories:

- Type A: Most stable, including clay and cemented soils.

- Type B: Medium stability, including silt, sandy loam, and previously disturbed soils.

- Type C: Least stable, including gravel and sand.

- OSHA classifies Stable Rock as natural solid mineral material that can be excavated with vertical sides and remain intact while exposed.

Proper identification and handling of soil types help in choosing the right protective systems.

- Access and Egress: OSHA mandates safe entry and exit points for trenches. Ladders, steps, or ramps must be provided in trenches 4 feet or deeper and placed within 25 feet of workers.

- Exposure to Falling Loads: Workers should be protected from falling loads. Heavy equipment should be kept away from trench edges, and materials should be placed at least 2 feet from the edge to prevent accidental falls into the trench.

- Hazardous Atmospheres: Trenches deeper than 4 feet must be tested for hazardous atmospheres, such as low oxygen, hazardous fumes, or toxic gases. Proper ventilation or respiratory protection must be provided if such conditions are detected.

- Inspections: Regular inspections by a competent person are crucial. A competent person is one who can identify hazards and has the authority to take corrective measures. Inspections should be conducted daily and after any condition changes, such as rainstorms

OSHA Trenching and Excavation

https://www.osha.gov/sites/default/files/publications/osha2226.pdf

Implementing Safety Measures

Ensuring safety in excavation and trenching requires a comprehensive approach that involves planning, health and safety training, and continuous monitoring.

- Pre-Planning: Before starting any excavation project, it is essential to conduct a thorough risk assessment. This includes identifying potential hazards, determining the soil type, and planning for appropriate protective systems.

- Safety and health training: Workers must be adequately trained in recognizing hazards and using protective systems. Occupational safety and health training should cover proper use of equipment, emergency procedures, and understanding OSHA regulations.

- Use of Technology: Advances in technology have significantly enhanced safety in excavation and trenching. For example, trenchless technology minimizes the need for open trenches, reducing the risk of cave-ins. Additionally, remote-controlled equipment can perform dangerous tasks without exposing workers to hazards.

- Continuous Monitoring: Safety in excavation and trenching is dynamic and requires ongoing monitoring. Regular inspections by a competent person ensure that any changes in conditions are promptly addressed. Monitoring also involves checking protective systems and ensuring that they are functioning correctly.

Where to Place the Excavated Material?

OSHA requires that the spoil, or excavated material, be placed at least 2 feet away from the edge of the excavation. This regulation is designed to prevent the weight of the spoil from contributing to a potential cave-in. Keeping the spoil at a safe distance also helps to ensure that it doesn’t accidentally fall back into the trench, posing a hazard to workers. Additionally, proper spoil placement helps maintain clear access and egress routes, enhancing overall site safety. Adhering to this requirement is a critical aspect of excavation and trenching safety and compliance with OSHA standards and regulations.

Case Studies and Lessons Learned

Examining real-life incidents underscores the importance of adhering to OSHA standards. In one notable case, a construction company faced severe penalties after a trench collapse resulted in a worker’s death. The investigation revealed that the company failed to provide adequate protective systems and proper occupational safety and health training. This tragedy could have been avoided by following OSHA’s regulations and implementing effective safety measures.

Conversely, companies that prioritize safety and adhere to OSHA standards report fewer accidents and improved worker morale. For instance, a construction firm that invested in comprehensive training and state-of-the-art protective systems significantly reduced its incident rate, demonstrating that safety and productivity go hand in hand.

Online Health and Safety Training

Online safety and health training offer a flexible and accessible way to educate workers on excavation and trenching safety. Safety and health training courses can be tailored to cover essential topics such as identifying hazards, proper use of protective systems, and emergency response procedures. Online safety training provides interactive modules that enhance learning retention and engagement. These safety courses allow workers to learn at their own pace, ensuring a thorough understanding of safety protocols. By incorporating workplace safety training into an online format, employers can ensure consistent and comprehensive instruction across all job sites. Additionally, online safety training can be regularly updated to reflect the latest OSHA regulations and industry best practices. Ultimately, online safety and health training empowers workers with the knowledge and skills needed to maintain a safe working environment in excavation and trenching operations.

Conclusion

Excavation and trenching are essential but hazardous construction activities. Compliance with OSHA’s Excavation standards, as outlined in 29 CFR Part 1926, Subpart P, is critical for protecting workers. By integrating comprehensive safety protocols, high quality safety and health training programs, and regular inspections, construction companies can proactively mitigate accidents and foster a safer workplace environment. This approach emphasizes that safety not only ensures regulatory compliance but also fosters a culture of care and responsibility, ultimately benefiting both workers and the organization.

Author: Dr. O’Neil G. Blake, Chief Executive Officer (CEO) of OSHAccredited Safety Institute

MS., MBA., MSc., BSc, CSP., ASP., CSHM., CSMP., MRSA.

Date: 05-27-2024